Transform Your Manufacturing Operations

Unplanned Downtime is Costing You More Than You Think

In today’s competitive manufacturing landscape, unplanned downtime and equipment failures can cripple your operations. Every hour of unplanned downtime costs manufacturers between 50 000 MAD and 500 000 MAD in lost production, with most companies losing 5-20% of their capacity due to unexpected disruptions.

Common Challenges Faced by Manufacturers:

● Unplanned machine downtime disrupting production schedules

● High maintenance costs due to reactive repairs

● Increased scrap rates from undetected machine inefficiencies

● Lack of visibility into equipment health and performance

● Difficulty identifying bottlenecks that slow down production

● Frequent overtime to meet missed production targets

Plex APM: Proactive Asset Health Monitoring for Maximum Efficiency

Plex Asset Performance Management (APM), a Rockwell Automation solution, empowers manufacturers to shift from reactive maintenance to predictive and condition-based maintenance, ensuring optimal equipment performance and minimizing costly disruptions.

How Plex APM Solves Your Biggest Pain Points:

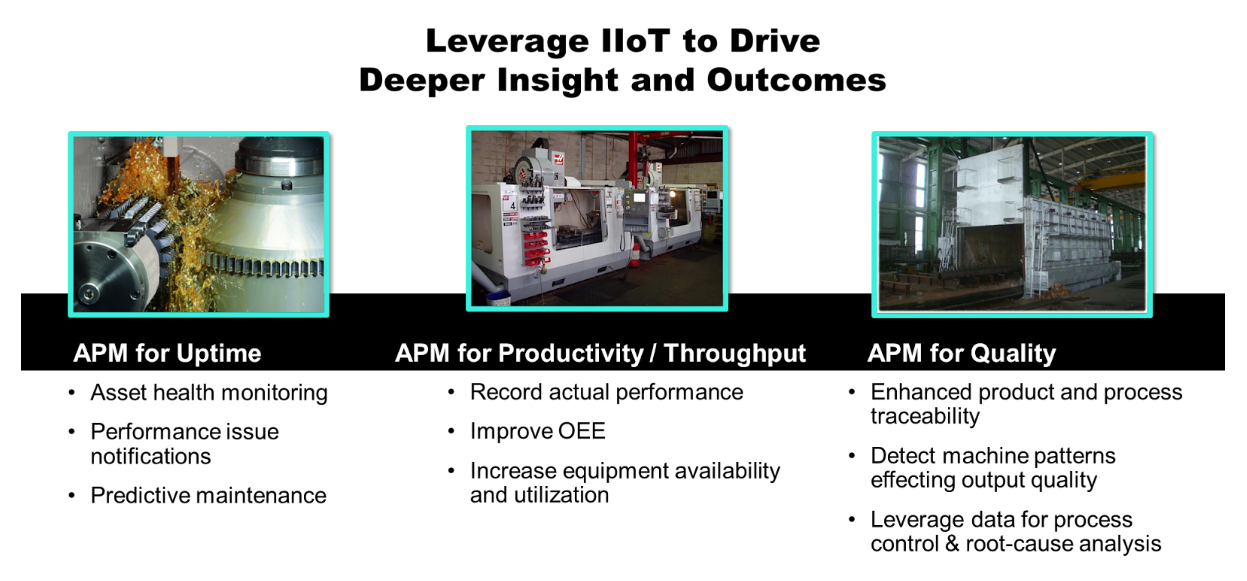

- Reduce Unplanned Downtime

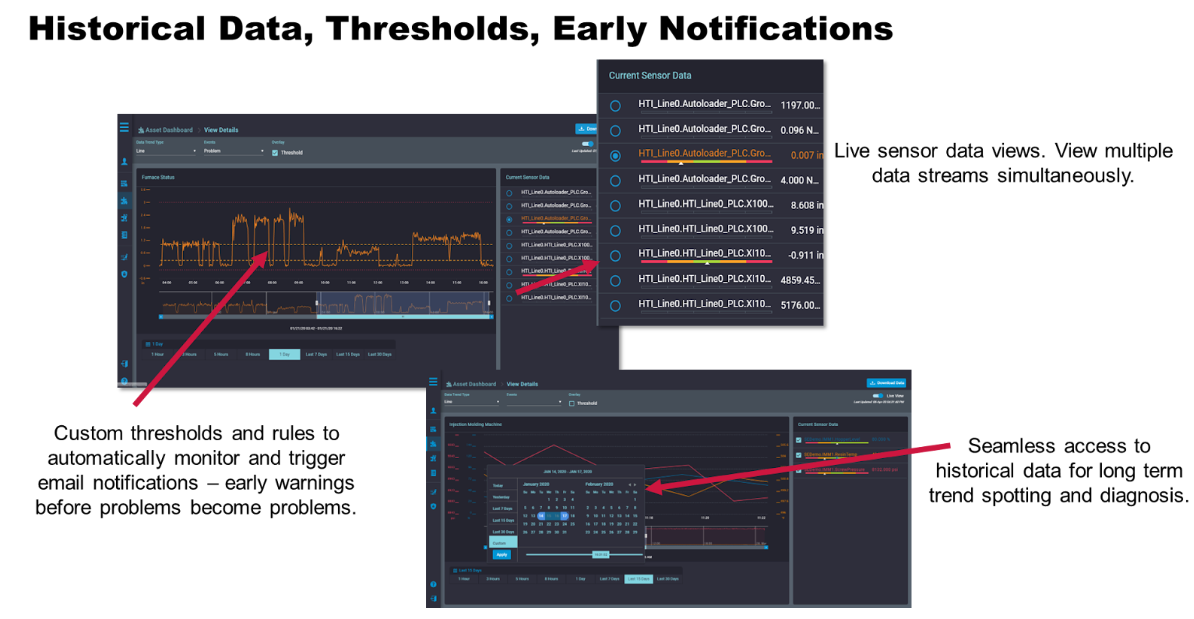

● Real-time machine health monitoring detects anomalies before failures occur.

● Automated alerts notify maintenance teams of potential issues.

● Historical trend analysis helps identify recurring problems.

- Improve Productivity & Throughput

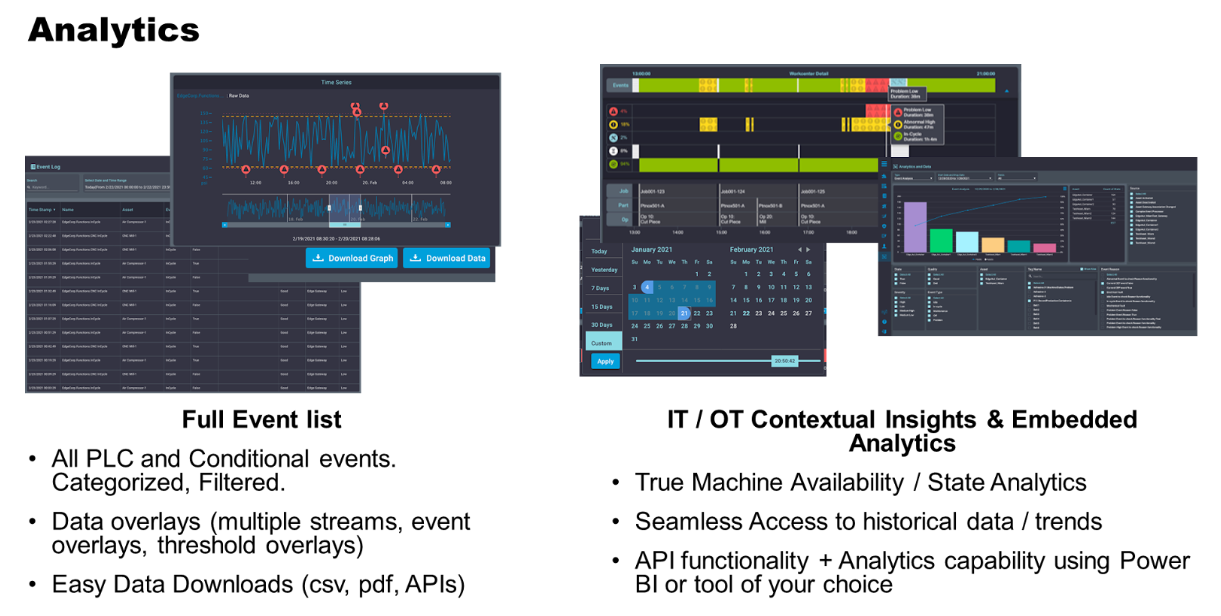

● Track micro-stops and downtime reasons for faster diagnosis.

● Optimize Overall Equipment Effectiveness (OEE) with actionable insights.

● Reduce job transition time by monitoring critical parameters (e.g., furnace temperature stability).

- Enhance Product Quality

● Detect machine patterns affecting output quality (e.g., washer stacking issues in heat treat operations).

● Root-cause analysis to prevent recurring defects.

- Lower Maintenance Costs

● Move from preventive to predictive maintenance, reducing unnecessary inspections.

● Integrate with Fiix CMMS to automate work orders based on real-time sensor data.

Proven Results with Plex APM:

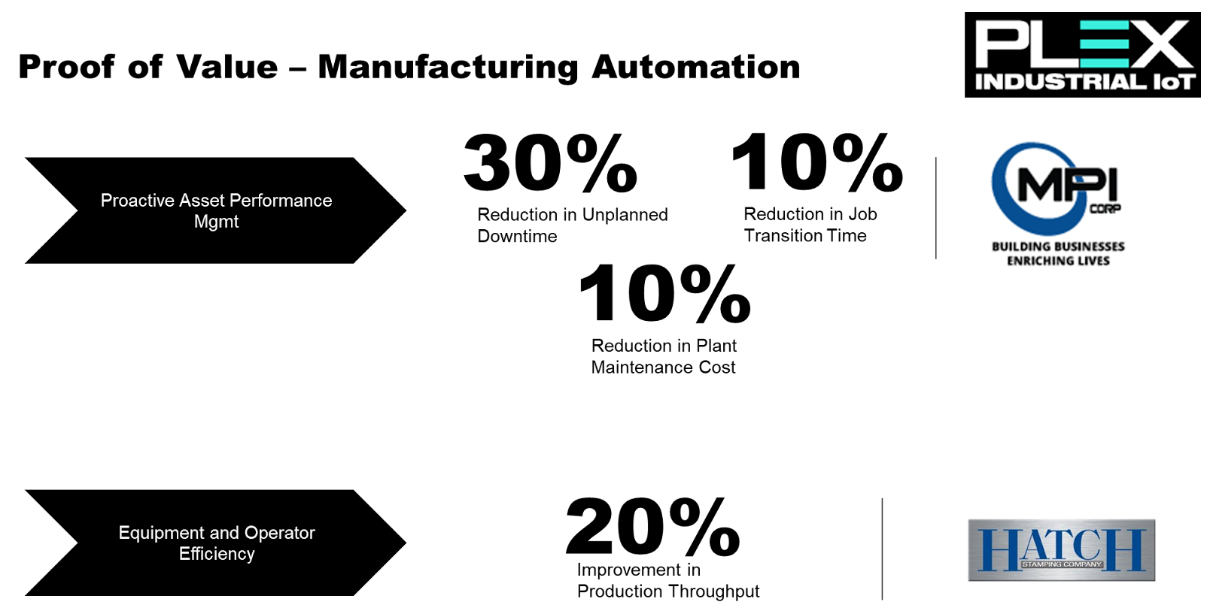

✅ 30% reduction in unplanned downtime

✅ 20% improvement in production throughput

✅ 10% reduction in maintenance costs

✅ 10% faster job transitions

Take the Next Step in Your Digital Maintenance Journey

Plex APM helps manufacturers evolve from basic monitoring to predictive maintenance, ensuring:

✔ Higher equipment availability

✔ Lower operational costs

✔ Improved product quality

✔ Data-driven decision-making

Why Choose IS Engineering as Your Plex APM Partner?

As a trusted distributor of Rockwell Automation solutions in Morocco, we provide:

● Expert implementation & support

● Customized training for your team

● Seamless integration with your existing systems

Ready to transform your maintenance strategy?

📞 Contact IS Engineering today to schedule a demo and see how Plex APM can optimize your operations!

🚀 Move from reactive fixes to predictive excellence with Plex APM!