FactoryTalk® DataMosaix™ | Industrial Data Hub for Smart Manufacturing

By IS Engineering – Premier Rockwell Automation Partner in MENA

Is Your Data Trapped in Silos?

In today’s fast-paced industrial landscape, manufacturers face a critical challenge: data fragmentation. Your valuable production, maintenance, and operational data is scattered across multiple systems—PLCs, MES, ERP, CMMS, historians, and more—making it nearly impossible to extract actionable insights.

The Cost of Disconnected Data:

● Slow decision-making due to lack of real-time visibility

● Inefficient troubleshooting with no unified root-cause analysis

● Missed optimization opportunities from untapped sensor and machine data

● High IT/OT integration costs with custom point solutions

Introducing FactoryTalk® DataMosaix™ – The Industrial Data Hub

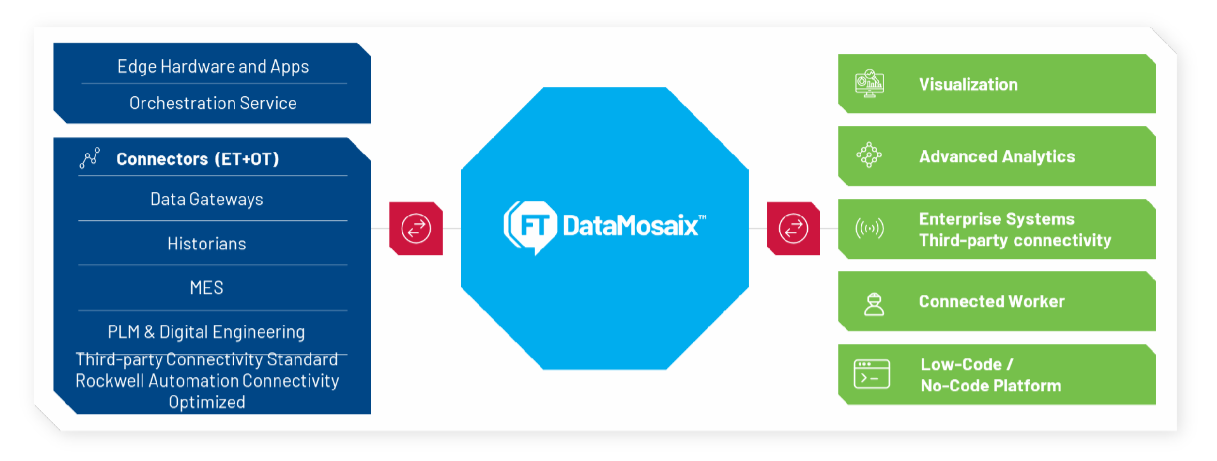

As a Rockwell Automation Partner in the MENA region, IS Engineering brings FactoryTalk DataMosaix, a scalable SaaS platform that connects, contextualizes, and transforms your industrial data into a single source of truth.

Why DataMosaix?

FactoryTalk® DataMosaix™ – the first industrial DataOps platform that:

✅ Connects all your OT, IT & engineering data in one hub

✅ Delivers real-time insights via dashboards and predictive analytics

✅ AI-powered contextualization – Automatically link machine data with maintenance records, drawings, and 3D models

✅ Scalable & secure – Cloud-based with enterprise-grade governance

How DataMosaix Solves Your Biggest Challenges?

For CEOs:

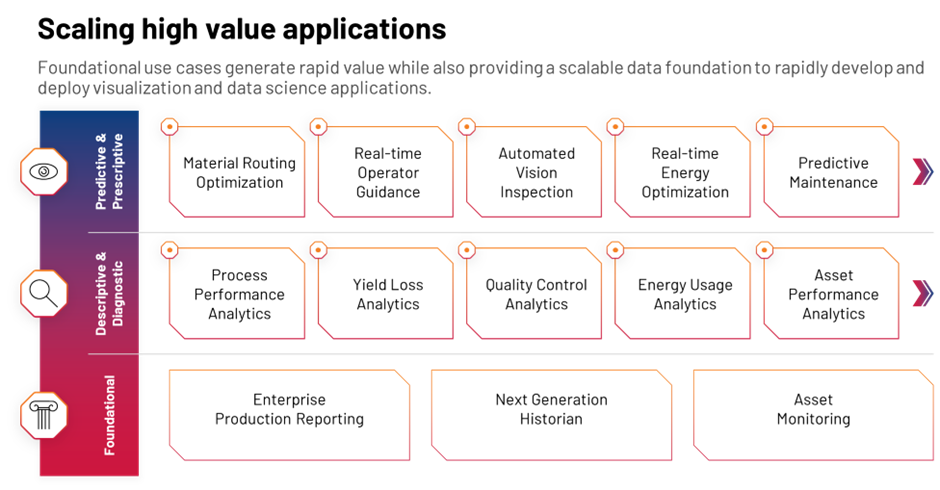

● 5-8% higher OEE through data-driven decisions

● 20-30% lower maintenance costs with predictive alerts

● Cloud-based SaaS – No upfront infrastructure costs

For Plant Managers:

● 35% faster root-cause analysis with linked:

○ Machine sensor data → Process diagrams → Maintenance history

● Real-time dashboards for OEE, quality, and energy use

For IT/OT Teams:

● Pre-built connectors to 30+ systems (SAP, OSI PI, MES)

● Zero-code analytics with drag-and-drop tools

● Enterprise security with role-based access

- From Fragmented Data to Unified Intelligence

● Connect any data source (PLCs, MES, ERP, CMMS, historians)

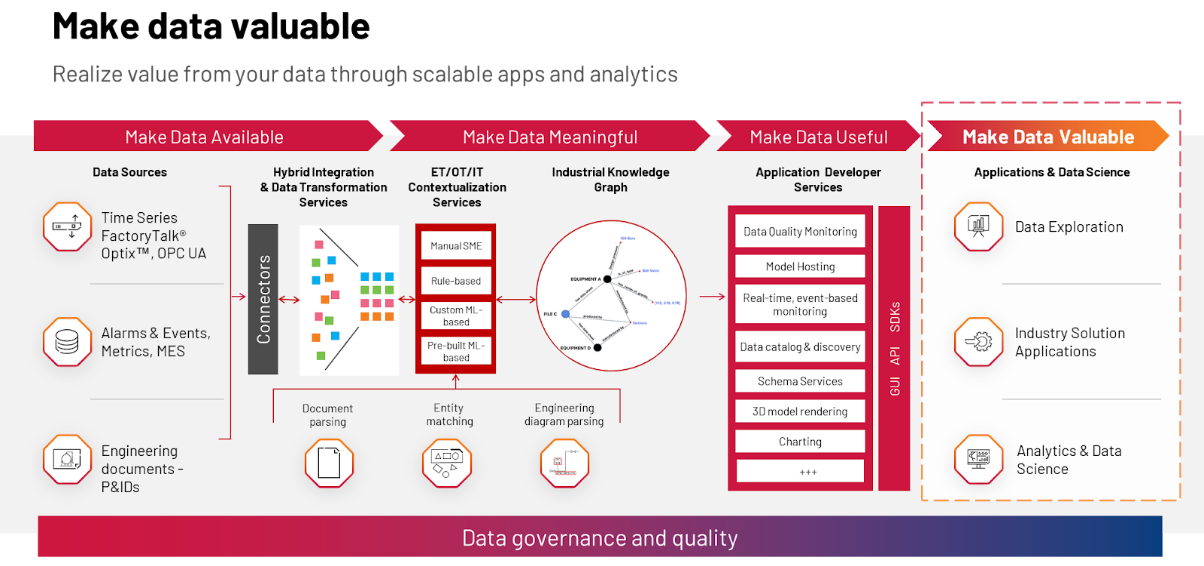

● AI-driven contextualization to map relationships between assets, processes, and events

● Industrial Knowledge Graph to visualize data like never before - Faster Root-Cause Analysis & Predictive Maintenance

● Correlate downtime events with machine sensor data

● Automated alerts for early failure detection

● Predictive models to reduce unplanned downtime by 5-8% - Empower Teams with Self-Service Analytics

● No-code dashboards for real-time OEE, asset health, and process performance

● Pre-built connectors for Power BI, Grafana, and Jupyter Notebooks

● Role-based access so engineers, operators, and executives see what they need

Proven Results with DataMosaix

📉 20-30% reduction in maintenance costs

📈 50-60% improvement in worker productivity

⏱ 5-8% reduction in asset downtime

Why Choose IS Engineering?

As a trusted Rockwell Automation partner in MENA, we bring:

✔ Deep manufacturing expertise – Tailored solutions for your industry

✔ End-to-end implementation & support – From integration to training

✔ Local Arabic/French speaking engineers

✔ Future-ready digital transformation – Scalable, cloud-based, and secure

Key Features:

● Industrial Knowledge Graph – See relationships between assets, processes, and people

● No-Code Analytics – Build dashboards without IT help

● Multi-Site Ready – Compare performance across plants

● Arabic UI Support – Fully localized for MENA teams

Ready to Transform Your Data into Actionable Insights?

🚀 Contact IS Engineering today to schedule a demo and see how FactoryTalk DataMosaix can connect your enterprise, optimize operations, and drive smarter decisions.